Introduction

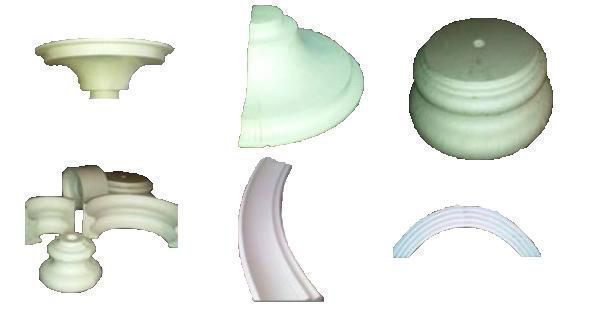

The hot wire CNC Foam cutting machine is to cut 2D shapes with thermocol foam materials,such as eps architectural decoration patterns,roman column,cornice ,decorative eps facade profiles, Styrofoam eps products,Eps wall panels,Styrofoam logo and letters and more product from Expanded Polystyrene Styrofoam etc.

Specification

| Item | Unit | PSQ3000 | PSQ6000 |

Cutting length

|

mm

|

3000

|

6000

|

Cutting width

|

mm

|

1250

|

1250

|

Cutting height

|

mm

|

1250

|

1250

|

Cutting shape

|

Axes(x,y)

|

2

|

2

|

Cutting speed

|

M/min

|

0-2000

|

0-2000

|

Power

|

kw

|

7.3

|

7.3

|

Voltage

|

V

|

380

|

380

|

Machine size

|

mm

|

3000x2600x2500

|

6100* 2600* 2400

|

Overall weight

|

kg

|

900

|

1100

|

Special Design

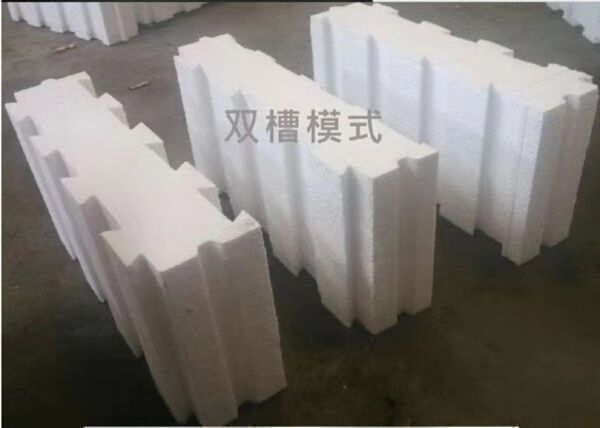

We have upgraded our machine as below picture,it cut with hot wire moving up and down,the working table move horizontally for 2D foam shape cutting.

The hot wire can be vibrated for better capacity and NF eps foam,the vibration unit installation is optional.If you choose vibration for the cutting machine,there is on/off button control for vibration as your working demand.You can see it on the video below.And it is open frame design.

Feature

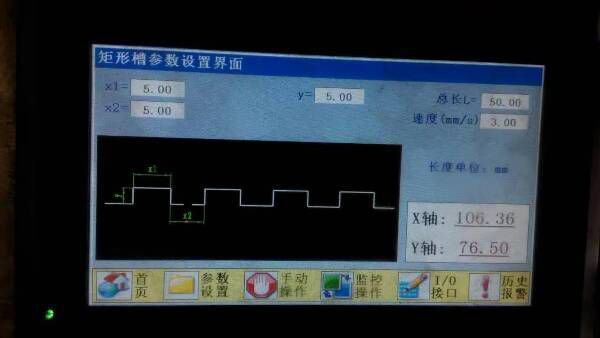

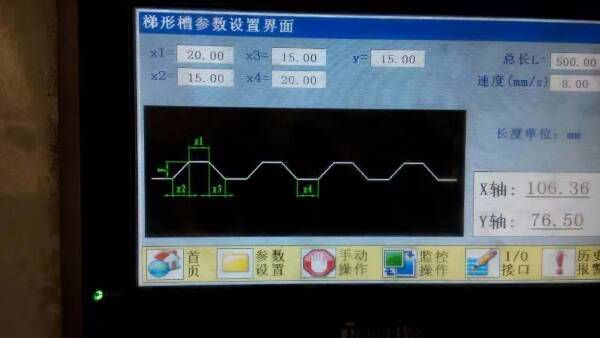

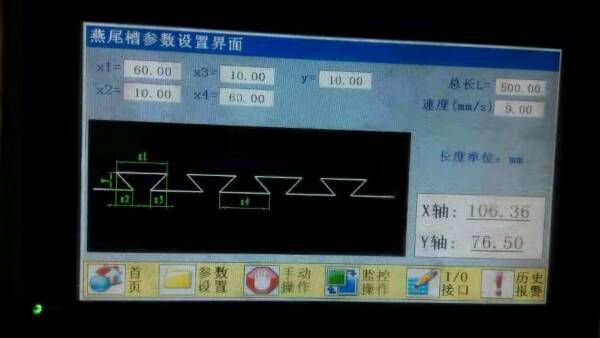

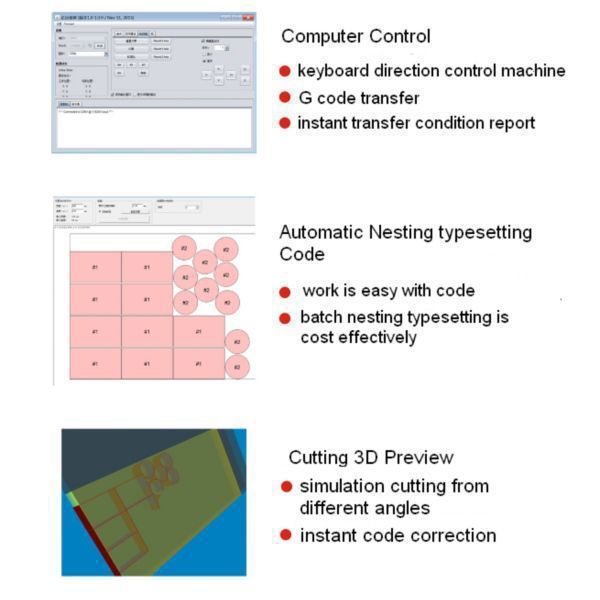

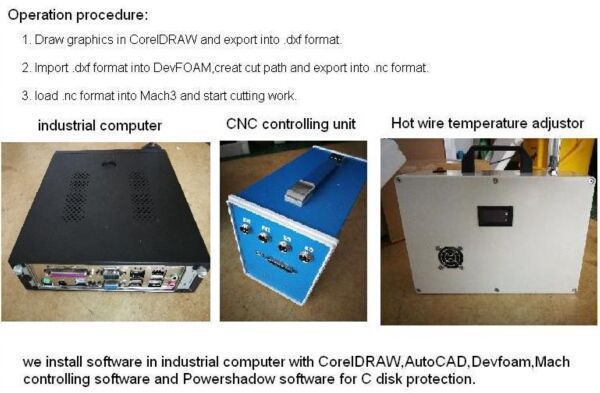

1) It works by computer via CAD software which signal X&Y axes synchronously for eps cutting products. You need design the pattern via AUTO CAD software, and X axis is for horizontal movement, Y axis is for vertical movement.

2) The machine structure is by rectangular pipe,sliding system is by linear module,both design can make the motion stable and cutting precisely.

3) The step motor enjoys with stable motion and free speed regulation,it is good for special shape cutting which requires variable speed.

4) Cutting frame can take 20 pcs hot wires which can max cut 20 pcs similar pattern and characters for 3m machine.

5) Machine functions with stroke protection,power cut memory,backlash compensation etc.

Warranty clause

We give one year warranty service. Parts are available free within one year in case of quality problem.

If you need more information about this 2D Hot Wire CNC Foam Cutting Machine, click here